A Routing specifies the sequence of that are required to manufacture the product. The operations related to produce the final product are performed at a Work Center or a Machine Centre, which is also referred to as facilities or capacities. Routing is mainly used by Manufacturing companies to manage the production process. The Routings are basis of:

- Process Scheduling

- Capacity Planning

- Manufacturing Documents

Routings are assigned to item cards in the same way as Production BOMs.

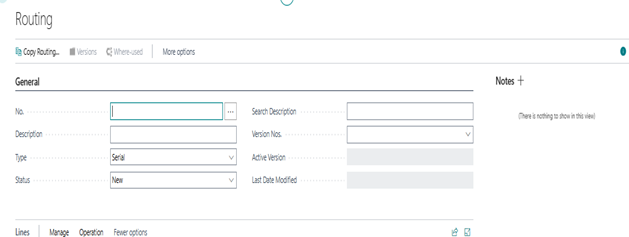

Routing Header Information

To create a Routing, you must define the Routing Header. This Header information Will apply to whole routing.

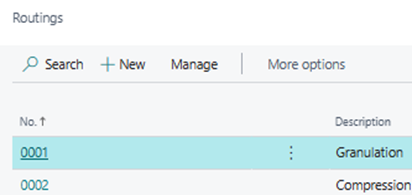

On the Routings list page, notice that the routing May has the same number as item. This is frequently the case when there is a 1:1 relationship between items and routings. But it is not a requirement (routing numbers are independent of item numbers).

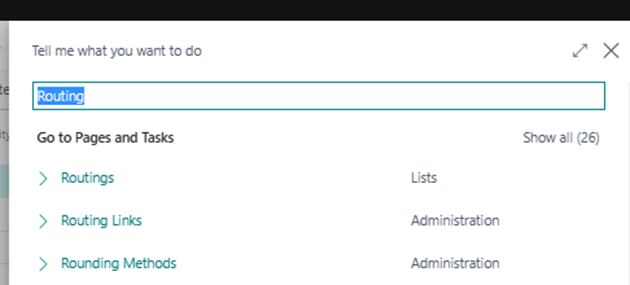

- In Search box type “Routing”, click on the related link

- On the Home tab of the Routings list page, click New

- On the General FastTab of the routing card, in the No. field, type Routing No.

- On the Home tab of the Routings list page, click New

- In the Description field, type required description in General tab.

- Types: - There are two types defined below, specification that defines the routing as serial or parallel.

- Serial - Indicates that operations are performed consecutively.

- Parallel - Indicates that two separate, unrelated operations can be performed at the same time.

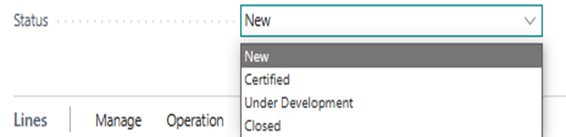

- Status of a routing. The following are valid statuses:

- New - The status is set automatically to New when you create a new routing. With new routings, you can edit the contents of the routing fields.

- Certified - You manually set the status of a routing to Certified when it is ready for production. Only certified routings are used for production orders and production planning. You cannot edit the fields of a routing if it is certified.

- Under Development - You manually set the status of a routing to Under Development when you want to edit it. Changing a routing to this status makes it possible to edit the routing fields. After you finish your edits, you must change its status back to Certified if you want to use the routing for production and planning again.

- Closed - You manually set the status of a routing to Closed when it is no longer used.

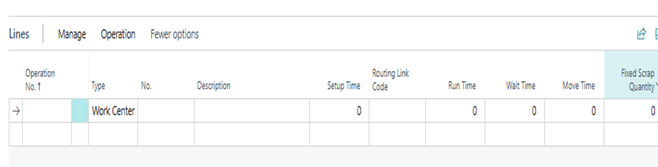

Create the routing lines

The routing lines basically define the operations related to routing (the steps in the production process) and are visible on the Lines FastTab. The contents of each line define its related operation. Except for the case of parallel processing, the values in the Operation No. field decide the sequence in which the related operations are performed. Detailed information is as follows:

- Operation no.- Operation number for the routing line used for various references. You can enter not more than 10 characters. Which includes both numbers and letters. The program species operations in the instruction/sequence of the operation number. We recommend leave a gap between operation numbers, such as 50, 60, 70, and so on. This helps to insert new operations between existing ones if needed.

- Type - It is for capacity type that is used for the operation. You can specify one of two types: Work Center and Machine Center.

- Other Information on the Routing Lines – Certain information copies to the routing line that is based on the type that you select. If you select Work Center, the following field information copies to the routing line:

- Setup Time Unit of Meas. Code

- Run Time Unit of Meas. Code

- Wait Time Unit of Meas. Code

- Move Time Unit of Meas. Code

- Machine Center link to a work Center – If you select Machine Center, the following field information copies to the routing line (if defined):

- Setup Time and Setup Time Unit of Meas. Code

- Wait Time and Wait Time Unit of Meas. Code

- Move Time and Move Time Unit of Meas. Code

- Fixed Scrap

- Scrap %

- Send-Ahead Quantity

- Minimum Process Time

- Maximum Process Time

- Concurrent Capacities

Steps for Creating Routing Lines

- On the Lines FastTab, in the Operation No. field, fill value.

- In the Type field, select Machine Center/ Work center according to need.

- In the No. field, select required one.

- In the Setup Time field, fill time if required otherwise it flow from related machine center if it was defined there.

- In the Run Time field fill time if required otherwise it flow from related work center if it was defined there.

- Move to the next row and type "20" in the Operation No. field.

- In the Type field, select Machine Center.

- In the No. field, as per requirement.

- In the Setup Time field, as per requirement.

- In the Run Time field fill time if required otherwise it flow from related machine center if it was defined there.

- Move to the next row, and then type "30" in the Operation No. field.

- In the Type field, select Machine Center.

- In the No. field as per requirement.

- Do not enter anything in the Setup Time field.

- In the Run Time field, as per requirement.

Certify the Routing

- On the General FastTab, in the Status field, select Certified.

- Click OK to close the routing card.